Sourcing – the first step to Buy Factory Direct from China

Since its inception, JS Sourcing has helped businesses beat their competition. We have successfully implemented lasting strategic sourcing and risk management in China for more than a decade. Our team’s familiarity with China’s industrial clusters, reliable China manufacturer networks whom we have been sourcing products from and years of hands-on experience are all assets we readily make available to our Clients. We plan, monitor and deploy local resources for businesses that buy factory direct from China.

Why sourcing suppliers with us

VERIFIED INFORMATIONFor better decisions

VERIFIED INFORMATIONFor better decisions FACTORY-DIRECTAccess to factory prices and industrial knowledge

FACTORY-DIRECTAccess to factory prices and industrial knowledge WEALTH OF RELIABLE DATAYears of sourcing experience

WEALTH OF RELIABLE DATAYears of sourcing experience INDUSTRY SAVVY TEAMFrom start to finish and more

INDUSTRY SAVVY TEAMFrom start to finish and more HASSLE-FREE PROCESSLet us handle all the heavy work

HASSLE-FREE PROCESSLet us handle all the heavy work

Our involvement in the purchasing and supply chain process does not stop at sourcing products from Chinese manufacturers. We can significantly reduce your team’s workload allover the buy products from China process. Give your team back the time they need to focus on merchandising and scale your business up. More than that, we dispatch our own people to the factories and workshops in China to conduct inspection services in China.

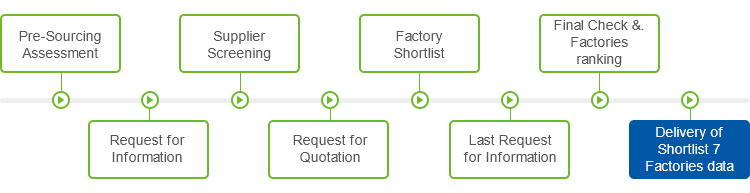

Sourcing the best manufacturers in China in 9 Steps

Pre-Sourcing Assessment

Our team evaluates your sourcing needs, market, targets and confirms feasibility. At this stage, JS Sourcing and the Client enter into an agreement over sourcing lead time and deliverables. Conclusions shared during this stage are based on years of sourcing, intimate knowledge of the Chinese industrial landscape and sourcing pitfalls.

RFI (Request for Information)

Sourcing experts start by identifying China manufacturers and suppliers, sends out RFIs (Request for Information). Information gathered during this steps ranges from product range, manufacturing output, previous experience, to available packaging, quality level and export capacity.

Supplier screening

Based on the data gathered from potential suppliers and own sources, we screen suppliers that meet the requirements of your project. Trading companies, one-man shows are put aside to focus on factories, workshops and value-added suppliers.

RFQ (Request for Quotation)

Screened suppliers are required to quote as per the Client project requirements. Sourcing specialists analyze costing structure and pinpoint inaccuracies, misunderstandings and missing information.

Factory Shortlist

Following to RFI and RFQ, our team proceeds to shortlisting the best China manufacturers based on their performance. We take into account a series of aspects such as degree of interest, costing, size, location, referrals.

Last Request for Information

One of our team members goes over the data with fresh eyes, identifies potential issues, missing information or inaccuracies. Last Request for Information are launched in order to ensure that the amount of information for each shortlisted manufacturing company in China is complete.

Final Check & Factories Ranking

Sourcing Supervisor conducts a final check of the Sourcing China manufacturers results. He or She highlights important information and issue a final ranking based on sourcing deliverables and Client’s profile.

Delivery of Shortlists and Factories Data

It is now time to deliver results to the Client. Following delivery, we usually set up a call or chat sessions in order to ensure that there are no questions unanswered.

JS Sourcing has been helping importing businesses source China manufacturers for years on end. Trusting us with sourcing reliable China manufacturers with competitive pricing is giving your business the chance to take over a bigger market share.

-

Find More Suppliers &

Find More Suppliers &

Products -

Minimize Your Risks

Minimize Your Risks -

Maximize Your Efficiency

Maximize Your Efficiency