Top China Inspection Services & Supplier Audit Services

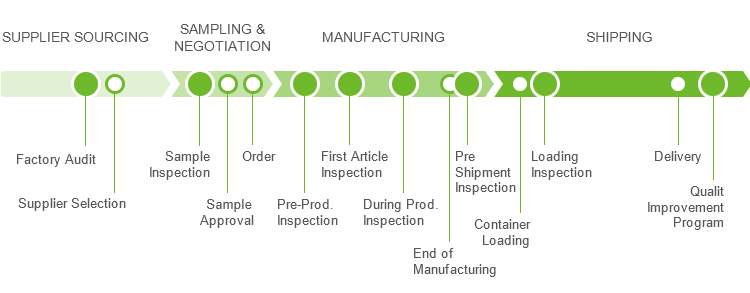

Every business success lies with a sound supplier pool. Nonetheless, the need for inspection services in China remains a reality. JS Sourcing has been conducting factory audits and quality inspections in China for more than a decade. Minimizing risks by implementing Quality Assurance at each step of the sourcing process in China is part of our core business.

Now considered a top China inspection company, JS Sourcing never stops improving its methods, increasing its efficiency and preventing defective products from being put on the market. JS Sourcing’s staff not only has a responsibility toward Clients but also consumers who buy products made in China.

Why choose us as your China Inspection Company?

Prevention is key to managing risks, especially in today’s supply chains. Nothing works better than smart and tailored China product quality checks. Our QC checks in Chinese factories are tailored to be fast and efficient Inspection reports providing accurate and sound results. Empowering purchasing teams abroad with enough material to minimize disruption and make informed decisions.

PREVENT DEFECTS & SHORTCOMINGS

PREVENT DEFECTS & SHORTCOMINGS ENFORCE QUALITY STANDARDS AND COMPLIANCE

ENFORCE QUALITY STANDARDS AND COMPLIANCE IMPROVE VALUE FOR MONEY

IMPROVE VALUE FOR MONEY MINIMIZE CONSUMER COMPLAINTS

MINIMIZE CONSUMER COMPLAINTS

It is our duty, as a leading quality inspection services company in China, to deliver easy-to-implement Q.C services with minimum disruption to our Clients’ operations in China. See below what quality China inspection services we offer :

1/ Factory audit

A Factory Audit is usually the 1st quality step that an importing business can take when sourcing in China. Our Quality Auditor travels to the factory premises and evaluates the manufacturing capacity, ability to meet delivery times, and performance in terms of product quality.

An audit service has the advantage to get real, hands-on intelligence about your future Chinese manufacturers. Our factory audit report allows importers to readily make an informed decision.

2/ Sample Inspection :

A sample inspection, or prototype inspection, is done by our Quality inspector before the Buyer places an order. The visual, dimensional checks and test results are all gathered into a detailed inspection report. We empower our clients with tangible, scientific data about the products they plan to order from China.

3/ Pre-Production Inspection (PPI) :

The Pre-Production inspection service focuses on checking the factory manufacturing equipment. JS Sourcing quality engineer performs checks to assess whether the production line, tools, and dies are in good working condition. During this check, we conduct an inventory of materials and parts needed for the finished product. A Pre-Production check is a sensible solution to take necessary steps when dealing with time-sensitive orders.

4/ First Article Inspection (FAI) :

This type of China inspection service applies more commonly to components and machined parts. Our Quality inspector conducts a thorough dimensional check, using specific quality inspection tools. FAI is a good choice when importing machined parts and components. This type of inspection is a preventive action aimed at minimizing the risks of non-conforming batches.

5/ During Production Inspection (DUPRO) :

DUPRO is a quality control performed when 20% to 80% of goods are manufactured. It involves a specific QC checklist and meticulous attention to manufacturing detail. Among other quality control services, this check not only focuses on the product but also the manufacturing process. Any defect or sub-performance detected is documented, and potential improvements are put forward.

6/ Pre-Shipment Inspection (PSI)

The most preferred product quality check in China. Pre Shipment Inspection is conducted on the factory floor by skilled quality engineers when 80% or more of your order is packaged. This is an important part of China’s inspection service and includes packaging (integrity, shipping mark, weight, and measurements) as well as the product itself. Upon receipt of our Quality Inspection Report, importers can easily know if a product is compliant or not, and which corrective actions to take if needed.

7/ Loading Inspection

Goods inspection during loading inspection is quick and concise. It is the final step of Quality Operations in China, at the warehouse, before products are loaded in a shipping container and exported from China. Loading inspection involves inventory, key product specifications, and loading supervision. Many importers book a loading inspection when buying from China. They get the assurance that their merchandise has been loaded and secured before shipment with minimum cost.

8/ Quality Improvement program

It is tailored to importing businesses committed to facilitating ongoing improvement of its operations. Our team takes all the data generated during your previous orders, and identifies and roots out inefficiencies and defects. Because each buyer has its own set of parameters, our Quality Improvement Program is tailored to the specifics of each foreign buyer enterprise and supply chain in China.

-

Find More Suppliers &

Find More Suppliers &

Products -

Minimize Your Risks

Minimize Your Risks -

Maximize Your Efficiency

Maximize Your Efficiency